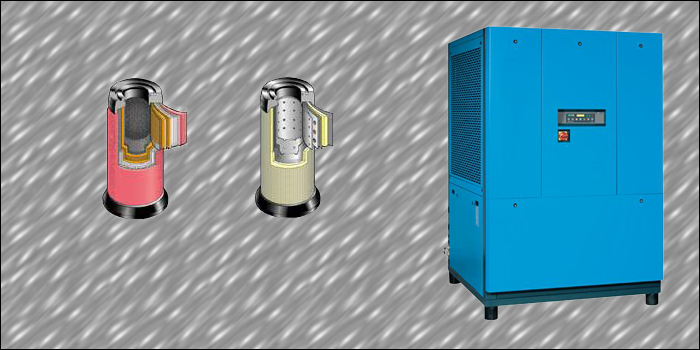

Lento VSD Oil Free Screw Compressor

Package includes rotary screw compressor, TEFC VSD main drive motor, filters, liquid cooler, stainless steel piping and water tank, cooling fan and controls for up to 145 psig air pressure.

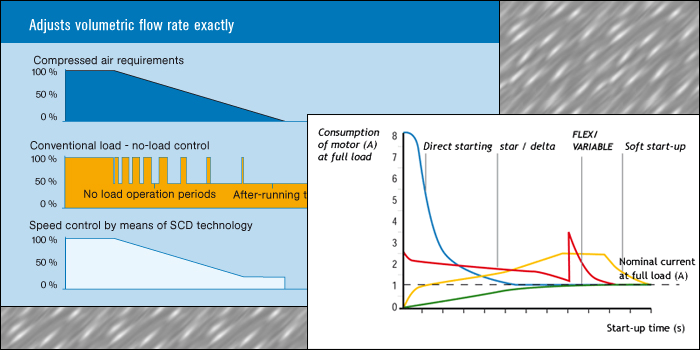

ALMS Series = Rapid Return On Investment

This Refrigerated Air Dryer has a 9% energy consumption (91% savings) at 0% load and can qualify for energy rebates!

Almig, a leading air system manufacturer, provides the best technology on the market!

Almig has a core product line that includes rotary screw compressors with all kinds of different drive system (BELT, GEAR, DIRECT), fixed speed and variable speed (VSD) up to 700 hp.