ALMiG Screw Compressors

ALMiG Flex Series

The ALMiG FLEX Series is a single stage, speed controlled, rotary screw line of compressors very similar to the VARIABLE series. Dating back to 1999, ALMiG was one of the first manufacturers of compressors to introduce variable speed technology. Combine that innovation and knowledge with the latest technology and research findings and you have the specially developed ALMiG FLEX Series. This series is perfect for applications where compressed air needs vary and need to be generated by a compact and extremely quiet plant, even directly in the workplace.

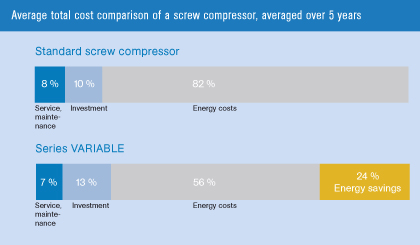

The average compressor usage is roughly 50-70% except at peak usage so a variable speed compressor will not cause unnecessary wear on your equipment and allows you to save on maintenance and energy costs. In response to this, ALMiG developed SCD (Speed Controlled, Direct drive) technology that allows the compressor to work their best exactly where it should; the partial load range. This variable speed drive regulates both flow and pressure by adapting motor speed depending upon the necessary load. This combination creates an extremely efficient compressor that could save you up to 35% in energy cost alone.

Protection of your equipment and necessary maintenance are important considerations as well. The ALMiG FLEX Series has many features designed for protecting the equipment such as soft starts and stops. A built-in shaft power monitor and a unique Load Curve Protection protect your process by immediately detecting any situation that could cause inefficiency or damage. This allows for early warnings and safety stops that assist with preventative action. If a problem does occur, a full status report is generated so corrective measures can be taken as soon as possible.

Features

- Compact build

- Single-stage

- TEFC, VSD drive asynchronous motor

- AIR CONTROL 3 microprocessor

- 1:1 transmission (no gear!)

- Oil-injection cooling technology

- Radial ventilator

General technical information

- Power rating: 3 - 40 HP

- Pressure: Up to 190 PSI(g)

- Flow rate: 7 - 143 CFM

- Cooling System: Air Cooled

Details

- Unit manufactured in accordance with ASME, OHSA and CE standards

- Vibration-isolated(compressor assembly isolated from the base frame), fluid-tight base frame. No foundation needed for installation!

- Sound insulation with dirt-repellant lining

- Integrated electrical control cabinet

- VSD direct power transmission to the air end through a flexible clutch

- Safe, fully unloaded start-up using ALMIG intake regulator with intake filter

- Oil separator reservoir for optimum pre-separation

- Oil separator cartridge for high compressed air quality with low residual oil content

- Large-area cellular radiator for oil and compressed air cooling and low compressed air outlet temperature

- Radial ventilator for optimum cooling and extremely low noise level

- Separate cooling air ventilator drive

- Emergency stop (Controlled by main switch